Head to any local bike shop or mega mart and hanging in a big long row you’ll see a huge lineup of shiny new wheels. All perfectly trued to a seemingly impossible level of perfection. Black spokes, silver nipples, freshly ground brake tracks, maybe a few absurd and awkward lacing patterns in the mix claiming some mix of stiffness and aerodynamic gain thanks to a very obviously made-up acronymic word. "F.A.K.E., Free Aero Kinesis Evolution”.

These are FACTORY WHEELS. These are the wheels you find lurking in the corner of every racers bike room, nearly every new bike, buzzing along on every trainer all winter…

Factory wheels are wheels that are manufactured in a distant factory by really neat looking robots for the mass market. These wheels come in all flavors but must also cope with all different types of cyclist. The same wheel must have a long service life for a cyclist who is 90+ kilograms, and for someone who is 60 kilograms. The heavier rider will likely see broken spokes every few months, and the lighter rider will have to suffer through wheels that are far too stiff.

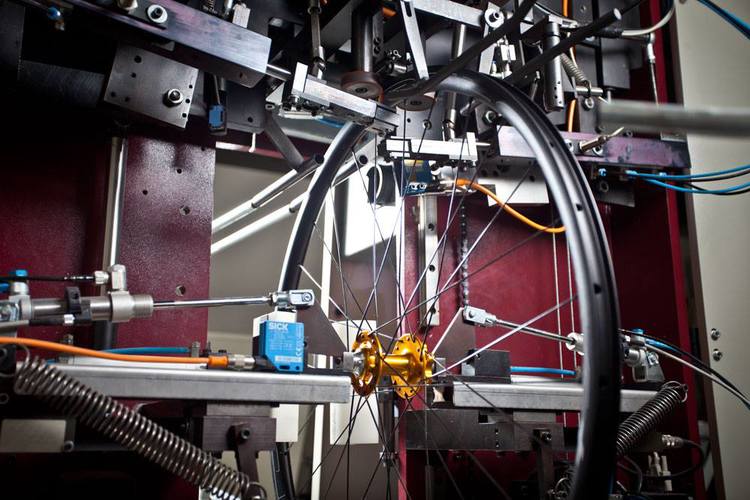

Wheel Building Machine

Because these wheels are built and tensioned so fast, in some cases in only a few minutes, with no real thought given to the material being used or any sort of technique, these wheels often have troubles right from the start. The “first 100km” tune and true see as a standard is a solution to a problem created by factory wheels. Spoke wind-up poor spoke tension release and two of the major culprits that lead to factory wheels going out of true in the first few rides.

At the bottom end you have factory built wheels that are priced cheap that will serve a acceptably long service life with a few broken spokes on the way to eventually wearing out all the non-serviceable components and being replaced. With the high-end of this class there wheels that are of a higher quality and that will serve a longer service life with minimal problems and using components that do have replacement parts, not coincidentally this is also the price class where handbuilt wheels begin.

Most factory wheels are built with less conventional spoke patterns, fewer spokes and odd spoke shapes. Marketing strategies like to get cyclists to associate these wheels with more aerodynamics and faster speeds and although there is some truth in it, the gains are minimal to non-existent and obtained when riding consistently above 30 kph, whereas the sacrifice of strength and durability is real, and at all speeds.

Alongside FACTORY WHEELS are other typical wheels like stock and branded wheels. Stay tuned, for parts two and three where stock, branded, factory handbuilt, and bespoke handbuilt wheels will be covered.